This classic design can be recreated and taken to the next level.

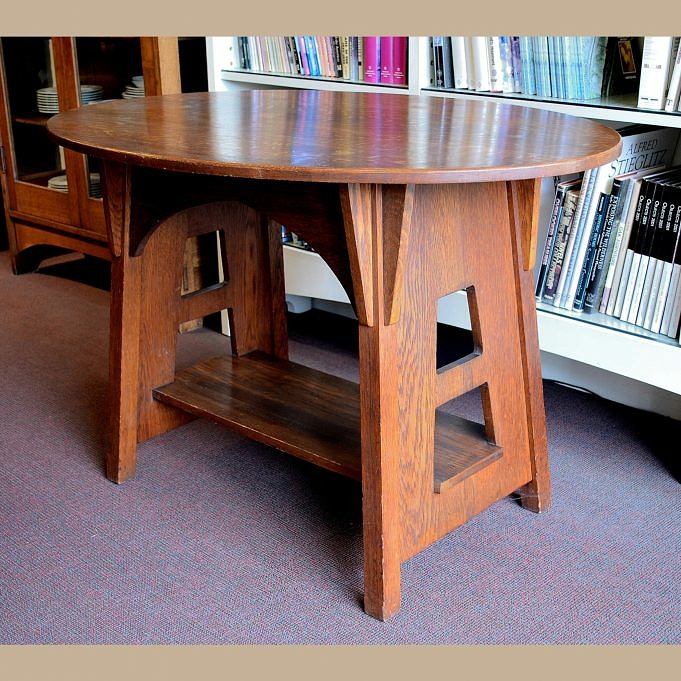

Of all the surviving Charles Limbert designs, there are three that stand out above the rest in my mind. One is the #355 Cottage Bookcase, and the second is the #153 Turtle Top desk. The third is the #146 Single Oval Library Table. Ive been fascinated with these pieces for years and inspired by the interesting use of shapes and angles in Limbert designs. With most Arts & Crafts style furniture, there is a deceiving level of complexity hidden in the design. With Limberts #146, the complexity is plastered all over the face of it. This table is easy to understand, with its compound angles, trapezoids and elliptical shapes.

The Single Oval table is a medium sized display table and would make an excellent perch for vases and collectibles. While most furniture from this era looks fantastic with heavy fleck Quartersawn oak lumber, I found myself reaching for rift sawn stock to build this one. Too many prominent profile lines and shapes can distract from the piece. Likewise, sapwood and flatsawn grain draws the eye away from the intended focal theme of this piece: its interesting shapes and angles.

Compound Angle Legs Get a plank made of 8/4 rift-sawn oak and create the four legs. These legs measure 13/10 cm in square and are approximately 76 cm in length. The legs are mitered and beveled, forming a compound angle. My father and I have another name for compound cut: we usually call them About a quarter inch short.

Complex angles can be difficult to work out, so make sure you have a consistent method for cutting them to length. I used a mitersaw and set the bevel angle at 5 and the miter angle at 5. Begin by cutting the leg at the compound angle. Next, slide the leg down the table keeping it in the same orientation. Then use a stop block to trim the legs to identical length.

Cut, Slide, Cut. Set both the bevel and miter angles to 5 and trim one end of the leg

Slide the leg leftward until it touches the stop block. Trim the leg to its final length.

Use a scrap block to make sure the point of the compound angle makes contact with the stop block.

Upper Leg Joinery

The upper third of each leg is where most of the joinery takes place. The arched rails join the legs with mortise and tenons, and the corbels feature stub tenons that sit in shallow grooves. Mark the extent of the

Each leg is given two mortises that are 3/10 cm in depth. Last, the remaining material is removed to a depth 1/4

The problem I encountered when cutting the grooves was interesting. Since the top of the legs are cut at a compound angle, my regular stop block wouldnt work. Instead, I created a single-point block that registers the center of the leg for the router table. I was able to mill the grooves on the legs at the same length from the adjacent sides. Use a scrap offcut from the legs to make the single-point stop. Make a hole in the top of your offcut. Tap in a 1/10 cm length of dowel. Set the stop block to allow a 23 cm long groove and clamp it to the router table fence. Chuck a 3/20 cm diameter straight bit into the router, with bit height set to 1/10 cm. Make a center cut on the fence and then mill two grooves for each leg.

The single-point stopblock is made from a leg ofcut and dowel to make the shallow grooves equal in length.

Trapezoid Templates

Glue all panels for the table, including the top, sides, arched rails and lower shelf. After the panels are removed from the clamps, cut the sides panels to a rough length of 261/10 cm and 41 cm. Next, create a template to cut the trapezoid shapes that will decorate each side panel.

Start by drawing the trapezoid shapes on one side panel. Lay 10 cm-wide plywood strips on your pencil. Measure between the strips and cut short cross-pieces to fit. Assemble this somewhat crude five-piece template with pocket hole screws.

Cut strips of scrap plywood and set them on your layout lines. Angle the ends of the short cross pieces approximately 7. Using pocket hole screws, attach the strips to form a quick frame

Now, clamp the frame to a piece

Finish shaping the template with a

This template can be used as a single template or to create a pattern.

Use a router with a 3/20 cm guidebusing and a 1/10 cm spiral bit to roughen out the shapes

So long as you take your time, and cut in multiple passes, it works quite well. I find it quicker and more accurate than a jigsaw, and now youre one step away from nice finished cutouts. You can switch to a bearing-guided flush trimmer bit and get rid of the remaining waste in one clockwise pass.

Get rid of any waste.

Taper and Spline

Legs are attached to the side panels using splines. But first, the side panels must be tapered at a 5 angle, which lets the legs lean in towards each other. Use a tapering tool at the tablesaw to adjust the panels to the layout. To accept the spline, mill the grooves into the sides. The groove should be about 1 inch below the bottom edge of the panel. This 1/10 cm deep groove is easily formed at the tablesaw with a 1/10 cm wide dado stack. Then reset the rip fence and make a centered groove in the legs as well. This groove should stop 33/20 cm from the bottom of the leg.

The tapering jig is quick to use for the side panel cuts. A wooden runner beneath guides the jig.

With a 1/10 cm wide dado stack, form stopped grooves in the side panels. A stop block clamped to the outfeed table limits the length of the cut.

Set the rip fence to make a center cut with the legs. Adjust the stop block and complete a stopped groove in each leg.

Turn the tablesaw blade to 5 degrees and make a bevel cut along the top of each panel. Once thats taken care of, youre ready for the leg subassembly. Mill up some spline stock to fit the grooves and glue each panel to a pair of legs. To keep clamps square, use the tapered offcuts for cauls. Focus on aligning their top edges as you clamp the parts together.

Tilt a combination blade to 5 and bevel the top of the panel. Use the left tilting saw to orient the workpiece toward the tablesaw. This light skimming job can be completed using large push pads and strong pressure. Another safety precaution for this operation is a riving knife.

Chisel the corners sharp, but only the lower corners of the larger trapezoid. This will allow the lower shelf to fit snugly without any visible gaps.

Glue the side assemblies together with 1/10 cm thick x

Arched Rails

The arched rails have angled sides but the joinery is very simple. Rip a pair of rails to 95/20 cm wide and cut them to a rough length of

Angle first, then tenon. After trimming both ends of the arched rail to 5, raise the tenons with a dado stack

Finally, trim the tenon shoulders with a handsaw.

While the dado blade is still on the saw, take care of the centered notch at the top of each arched rail. To support the rail at the required angle, position it against the miter gauge. The notch is 21/20 cm deep and 7/20 cm wide. Then switch to a standard tablesaw blade and bevel the top edge of the arched rail to 5, just as you did with the side panels. If you have a left-tilting saw, orient the show face downward as you complete these bevel cuts.

Dado notch for cross rail. To position the arched rail in front of the blade, use a scrap block that is angled to 5. Use a miter gauge to guide the rail slowly over the dado blade.

The final process for the arched rails is to cut the curved shape. Mark the Tudor style curve and cut close to your line at the bandsaw. Finish the shaping with a spokeshave. Sand it smooth. At this point its advisable to test the rails, and check that all the angles come together as they should.

Only after the joinery has been completed for the arched rail, including beveling the top edge, can you mark and trim your Tudor-style arch. Cut close to your layout line at the bandsaw, and refine the shape with a spokeshave, file and sandpaper.

Cross Rail and Corbels

You might be tempted to change the plans so that the cross rail notch is a true half-lap. I recommend that you only notch the arched rail and not the crossrail. You will end up with a difficult puzzle that can only be assembled one way, and it may prove difficult to fit. Cut the cross rail piece to your desired shape. Place the cross rail in place and admire your work. Its this stage of the project that you see indelible progress as the table starts to take shape.

Angle the cross rail leaving the end profile 7/20 cm square. Plan the angle and make elongated holes to mount the top.

Form the eight corbels and the stub tenons that will match the grooves on the legs. The corbels need to be trimmed at a compound angle to meet the underside of the tabletop. The lower end of the corbels are trimmed in a similar manner. Tilt the tablesaw blade to 5 and angle the miter gauge to 5 as well. Trim four corbels with the miter gauge angled to the left, and the remaining four corbels with the miter gauge angled to the right.

For corbels with uniform length, use a stopblock on an auxiliary fencing.

Corbel blanks. Raise stub tenons on the corbels, sized to fit the groove. Form compound angles at the top- and bottom.

With the blade tilted 5, angle the miter gauge 5. The compound angles are just like the legs: cut, slide, cut.

Lower ShelfThe shelf juts out the through the lower trapezoid, giving the impression of a through tenon. The projection of the shelf is cut at 7 angles to ensure that the parts can be mated. To fully fit against the side panels, the shoulders of the shelf have been cut at a 5-degree angle. The angled notch is readily handled at the bandsaw by tilting the table left or right. Start by measuring between the side panels of the dry assembled table. The shelf is measured from the bottom of the lower trapezoid. To complete the bandsawn cut, you will need to use a copingsaw. Finally, drill four pocket holes on the underside of the shelf.

Angle the bandsaw 5 upward to complete the first two shoulder cuts. Next, adjust the table to 5, and make two more shoulder cuts.

The Elusive Ellipse

Sand the parts youve made and glue the table together. Once the glue dries, you can sand the tabletop panel and set up a router or jig for cutting the ellipse. While there are commercial jigs available, I wasnt able to find one that could cut the 114 cm x 76 cm size required. I instead built a simple tool that could deal with the large differences between the major radius (and minor radius) (See page 56 for detailed instructions on making your own ellipse-cutting jig.)

Use a plunge router with a 1/10 cm spiral-upcut bit to cut the tabletop in multiple passes. Next, make micro adjustments to create a smaller ellipse. Youre looking for a small change here-just enough to clean up the bit marks from the initial passes. You are now ready to go. Sand the top, smoothen the edges and use a roundover bit.

Cut out the elliptical-shaped top in multiple counterclockwise passes. To remove the router bit marks, reset the jig and make a complete trimming pass.

Final Details

Glue corbels together, making sure they are flush with the legs. Counterbore holes in the underside of the cross rail to serve as screw holes for mounting the top. To allow wood movement, the outer holes must be extended. Attach the crossrail to the arched rails.

When gluing the table frame together, loosely insert the shelf (without glue), and focus on aligning the arched rails with the top of the legs as you tighten the clamps. The lower shelf will be attached in a separate step. Painters tape holds the long angled cauls in place

Glue two corbels to each leg, making sure the parts are flush at the top

The lower shelf is attached using four screws with a pocket and one pair of glue blocks, just like the original. Angle the blocks to fit, and glue them in place with 18 gauge brad nails. To avoid a cross-grain glue joint, the blocks are made from an end grain laminate.

Attach the crossrail to the notches using a pair screws. Make sure there is no gap between cross rails and arched rails.

Recommendations for Product

These are the tools and supplies we use every day in our shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.